Calculating the reduction of impact when using Self-Healing Concrete

The lowered impact of a river lock’s concrete is made visual with our new calculation tool

The Project

Basilisk Self Healing Agent is to be used in the concrete mix for a river lock in Great Britain. The concrete is constantly in contact with water, making it a perfect fit for Healing Agent to make the structure watertight.

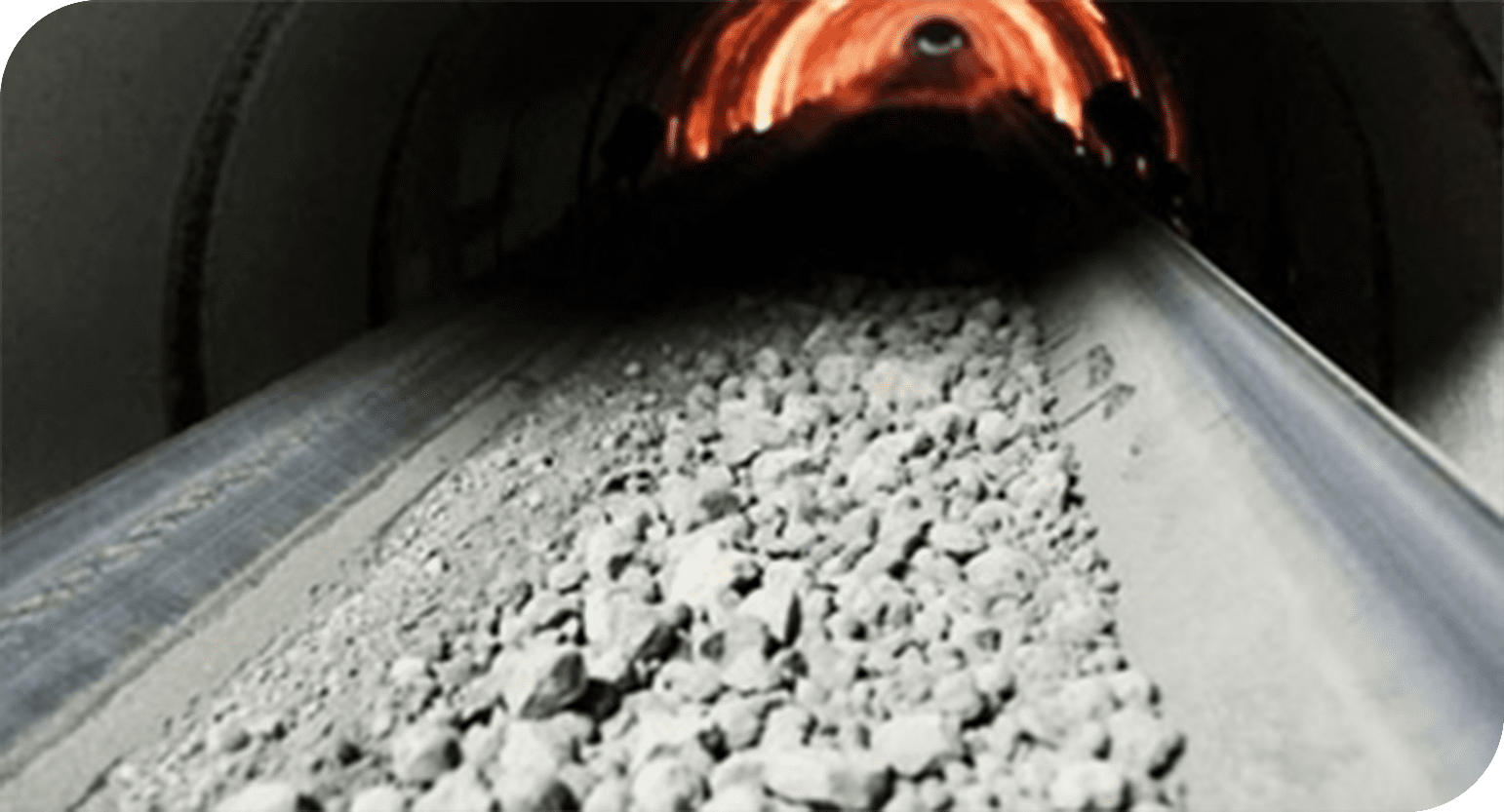

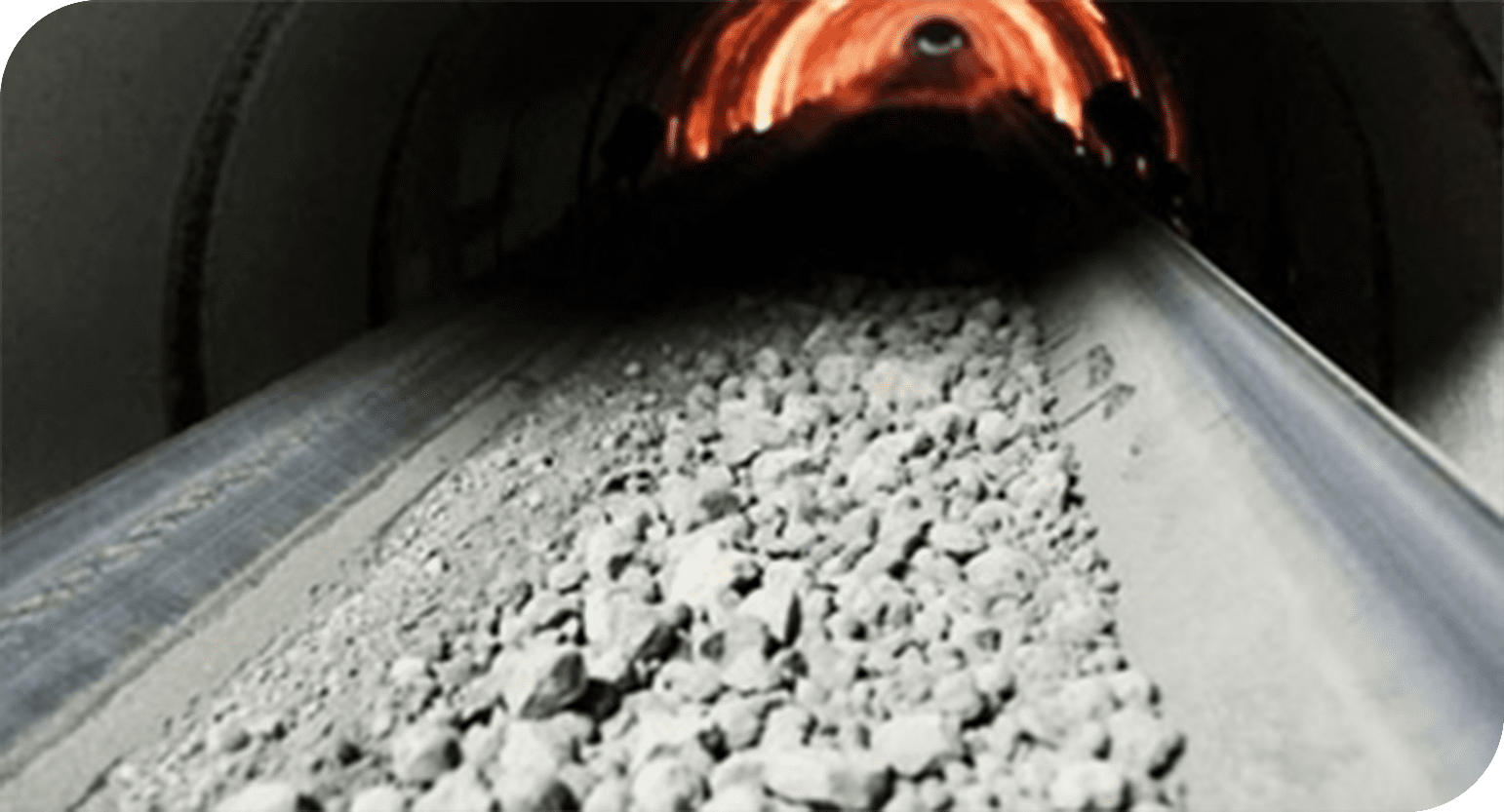

Cement & CO2

Commonly CEM I cement (NEN-EN 197-1) is used with a high percentage of clinker. The production of clinker causes high amounts of CO2 being emitted. A way to reduce this is by using cement with a lower percentage of clinker, complemented with furnace slag, a residue from the production of steel.

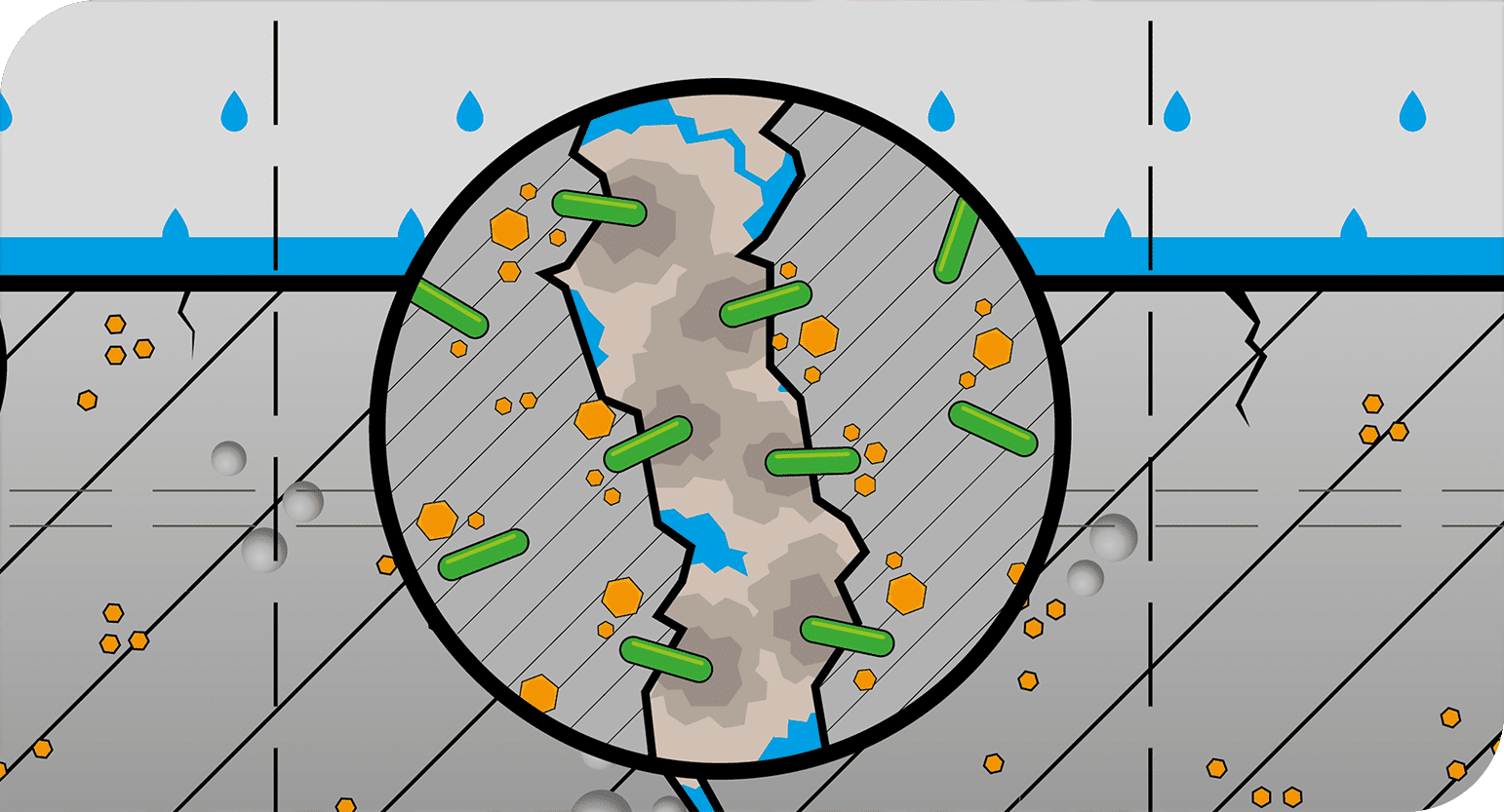

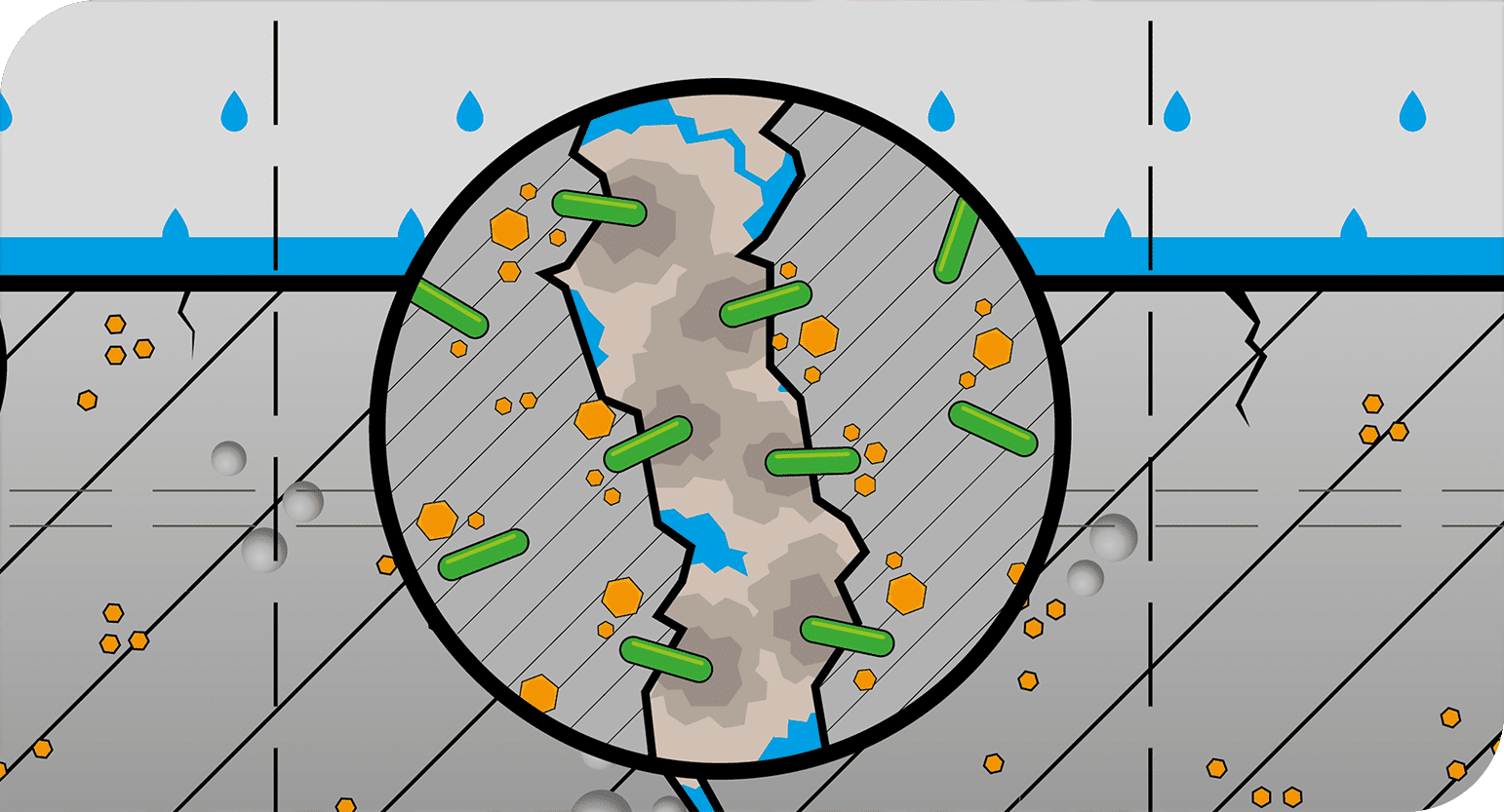

Vulnerability to leakage

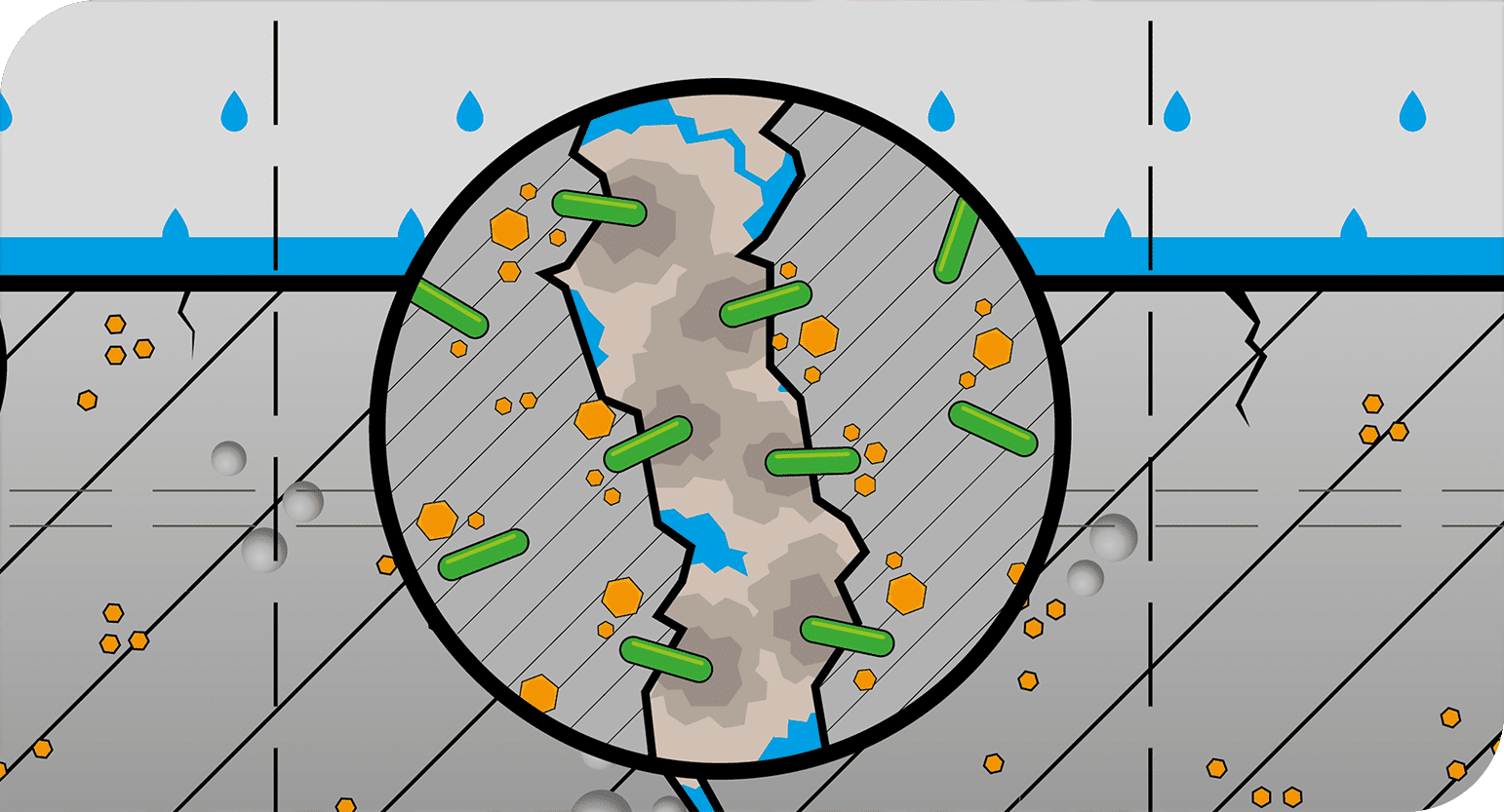

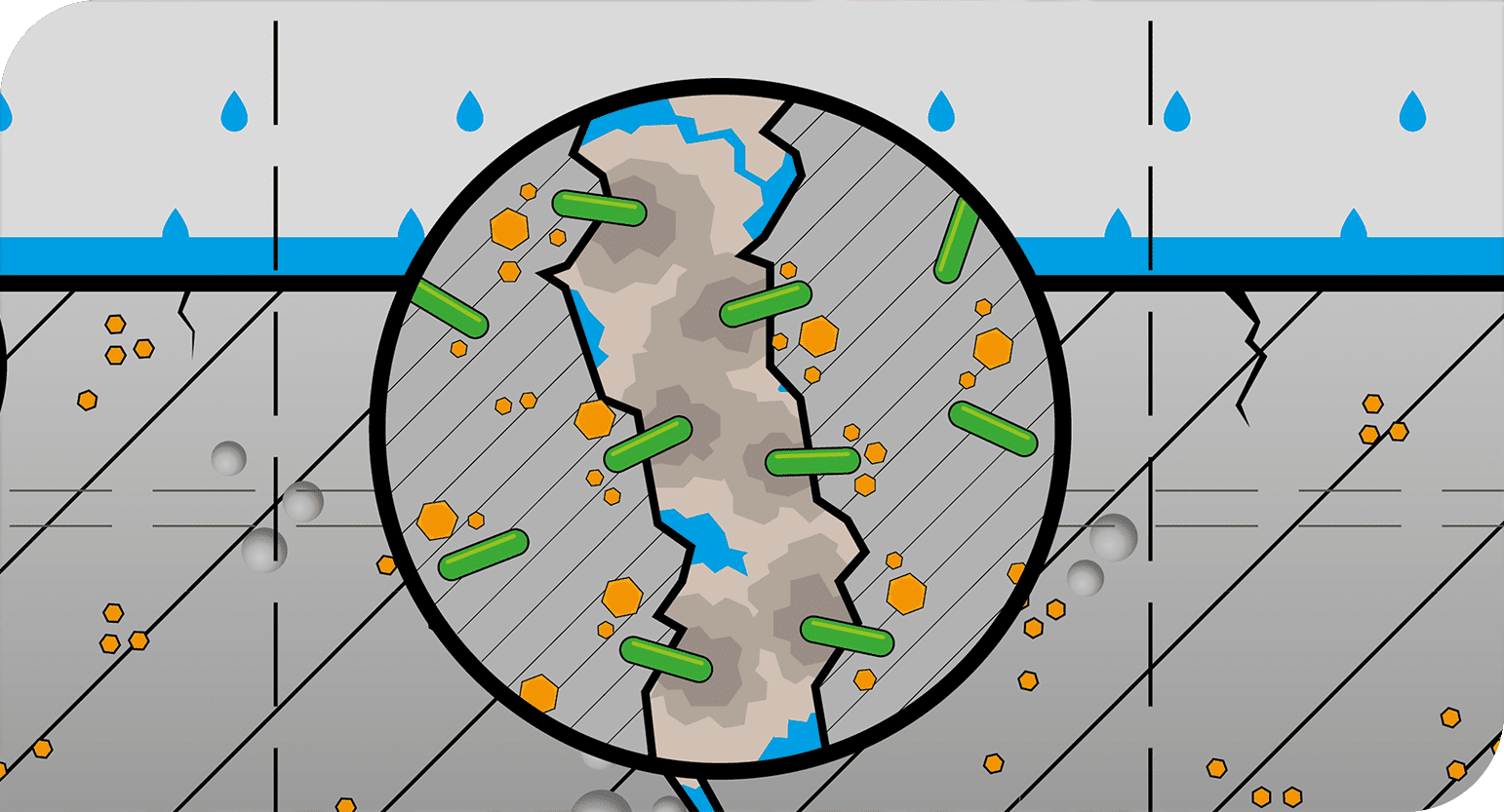

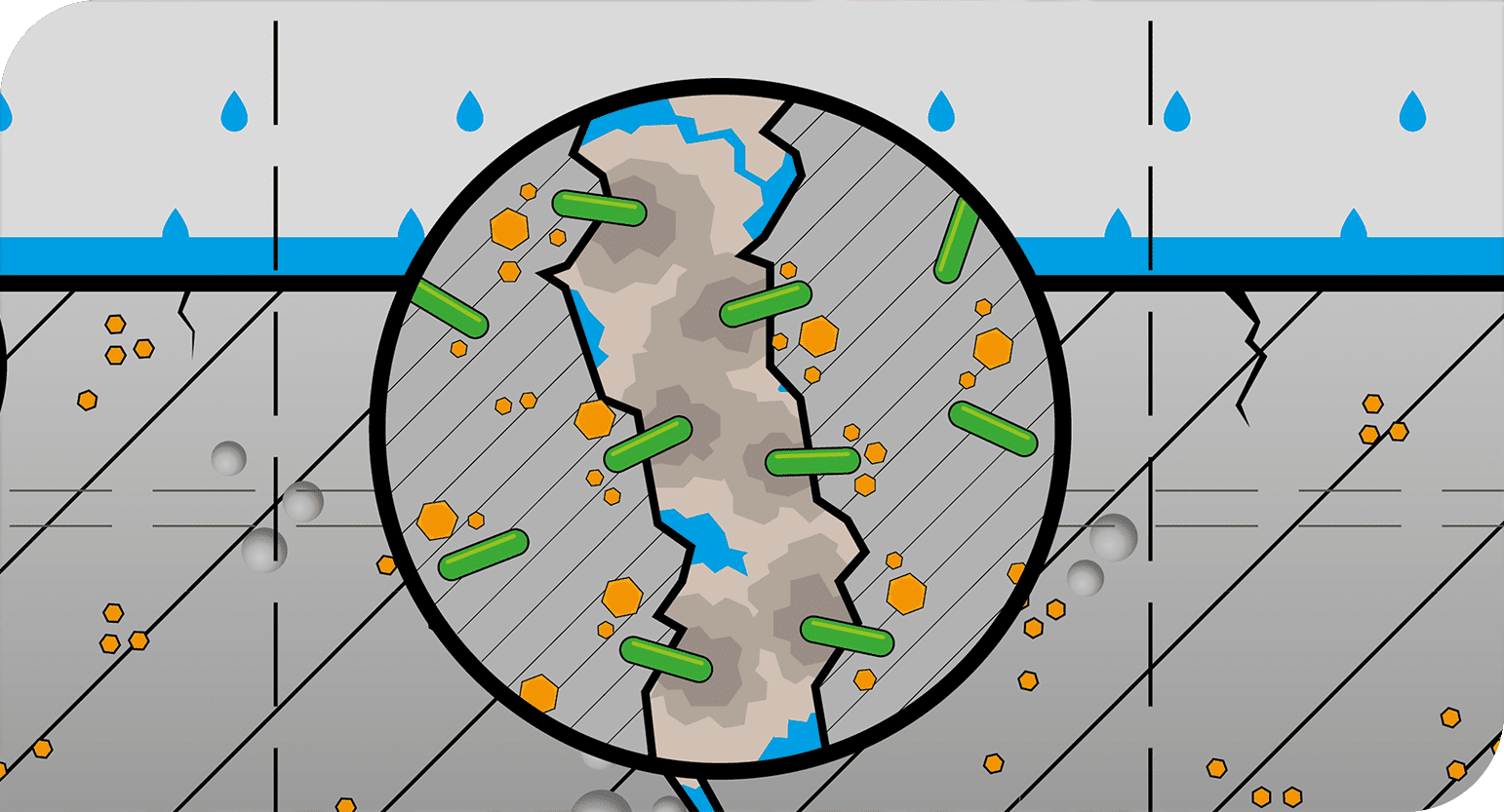

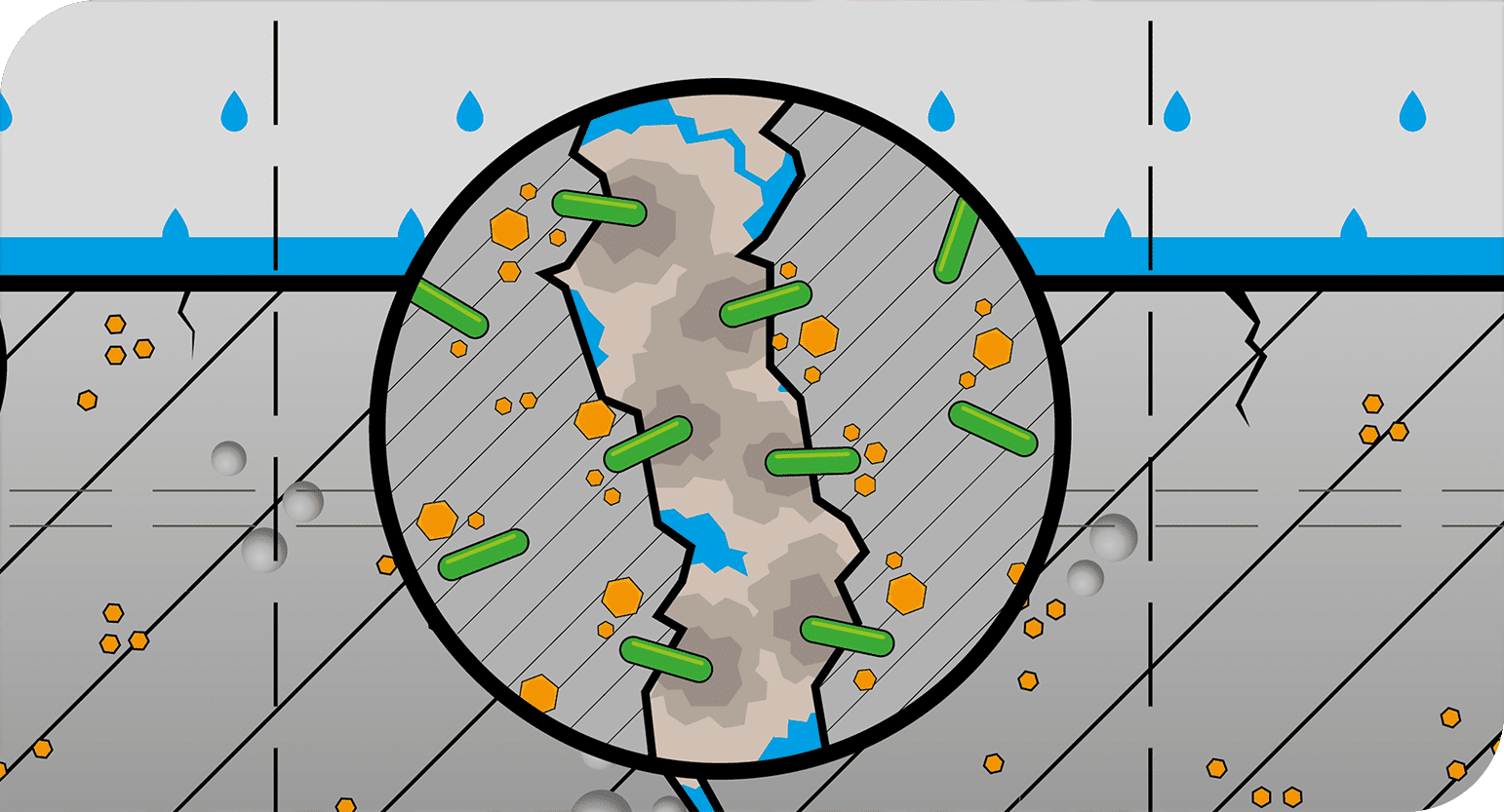

Even though it is better for the environment to use a cement with less clinker, such as CEM IIIA, it does have a downside. The ability for autogenous healing in concrete is negatively affected, making it more vulnerable to leakage over time. If these cracks are not repaired in time, water will reach the reinforcement and can cause steel corrosion.

Making concrete repair itself

With Basilisk Healing Agent, the ability for the concrete to heal itself is restored and even significantly improved. The bacteria in the Self-Healing Agent are activated by water and starts to produce limestone. This seals cracks and makes the structure watertight. This in turn makes the concrete more durable, and the overall CO2 footprint of the river lock’s concrete structure is lowered by 25%.

The Project

Basilisk Self Healing Agent is to be used in the concrete mix for a river lock in Great Britain. The concrete is constantly in contact with water, making it a perfect fit for Healing Agent to make the structure watertight.

Cement & CO2

Commonly CEM I cement (NEN-EN 197-1) is used with a high percentage of clinker. The production of clinker causes high amounts of CO2 being emitted. A way to reduce this is by using cement with a lower percentage of clinker, complemented with furnace slag, a residue from the production of steel.

Vulnerability to leakage

Even though it is better for the environment to use a cement with less clinker, such as CEM IIIA, it does have a downside. The ability for autogenous healing in concrete is negatively affected, making it more vulnerable to leakage over time. If these cracks are not repaired in time, water will reach the reinforcement and can cause steel corrosion.

Making concrete repair itself

With Basilisk Healing Agent, the ability for the concrete to heal itself is restored and even significantly improved. The bacteria in the Self-Healing Agent are activated by water and starts to produce limestone, sealing off the cracks watertight. This in turn makes the concrete more durable, and the overall CO2 footprint of the river lock’s concrete structure is lowered by 25%.

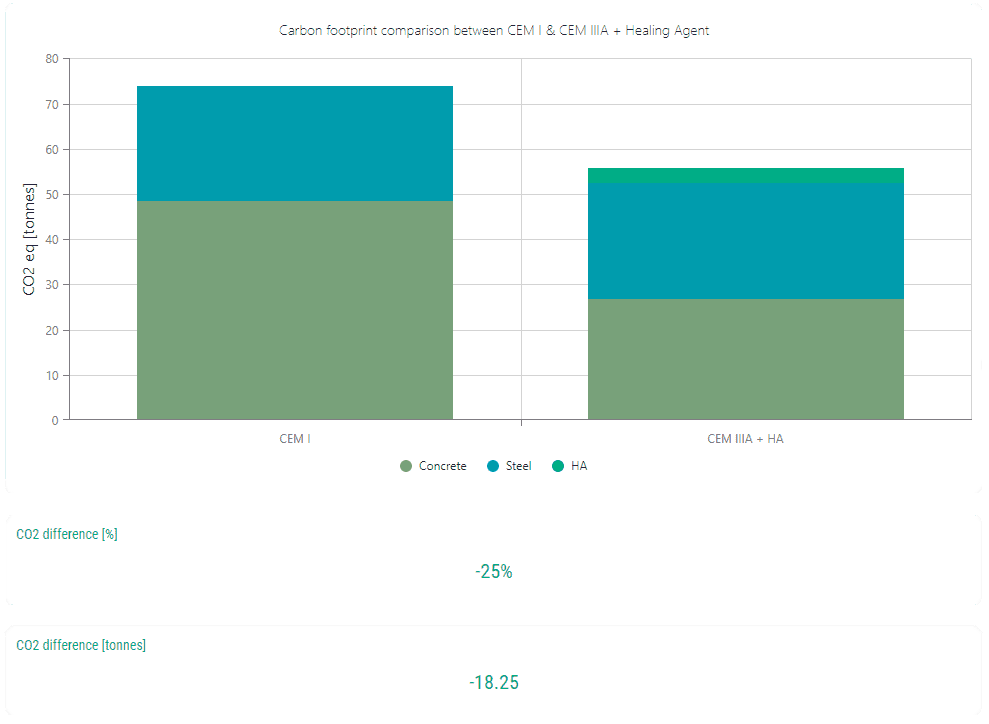

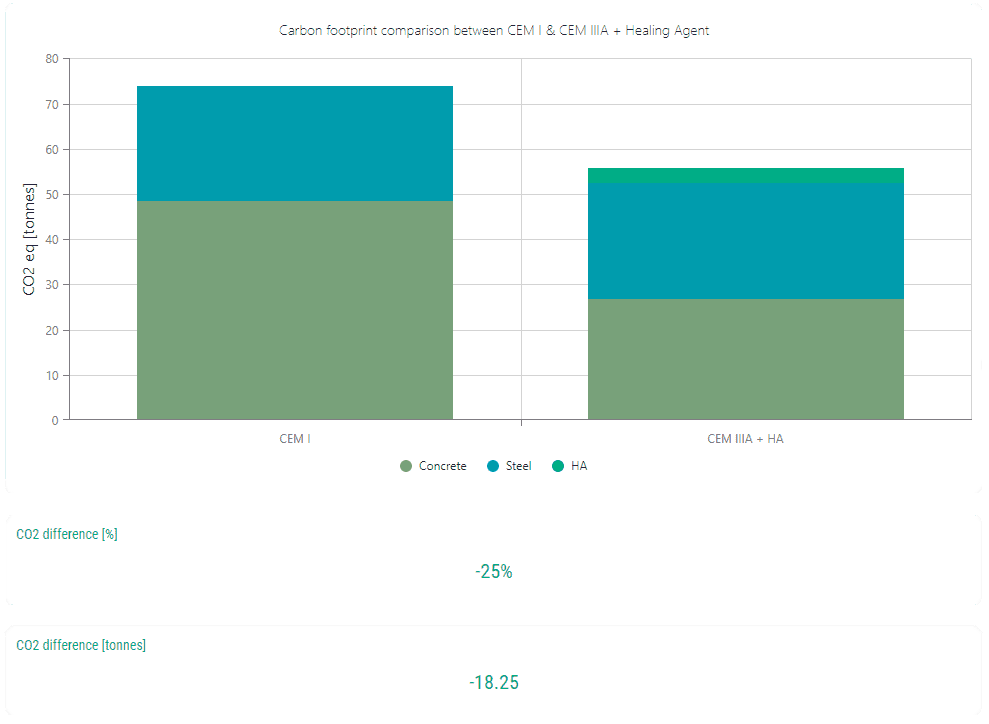

CO2 reduction calculated

With the river lock’s project specifics an initial calculation can be made to show the reduction of CO2 emissions. In the figure on the right you can see the drastic lowering of CO2 due to changing the type of cement and the small amount of emissions the Healing Agent causes to make the concrete self-healing. With the tool below you can make a comparison for your own project.

Calculation tool

With the project’s specifics it is possible to calculate the emissions for the production of the concrete. The Dutch National Environmental Database (NMD) was used as a source for the calculation of the emissions. This tool can give a simple indication of the CO2 emissions that are caused by the production of the concrete in your project. Simply enter the amount of concrete, the amount of steel reinforcement and see what amount of CO2 can be saved if the cement is replaced and Healing Agent is added. For this calculation 80 [kg/m3] steel reinforcement is used, contact us to tailor this calculation to your project specifications.